Multi-Disciplined Product Architecture

Due to technology limitations of the past, ground and airborne instrumentation systems were comprised from an array of single purpose units which made up a total system. With ever increasing component miniaturization and System on a Chip (SoC) technologies, Telspan Data has developed a range of products with a “Multi-Disciplined Architecture” that provide complementary capabilities with significant performance improvements over legacy hardware.

These capabilities can range from adding GPS & network timing in an Ethernet switch or including FPGA’s for protocol translation & data filtering schemes all the way to providing high speed recording capability with simultaneous filtering, processing and conversion for telemetering data. Several solutions are presented which benefit budgets by decreasing box counts, reducing integration efforts, benefiting SWaP (Size, Weight and Power) and constrained implementations all while increasing overall system capabilities.

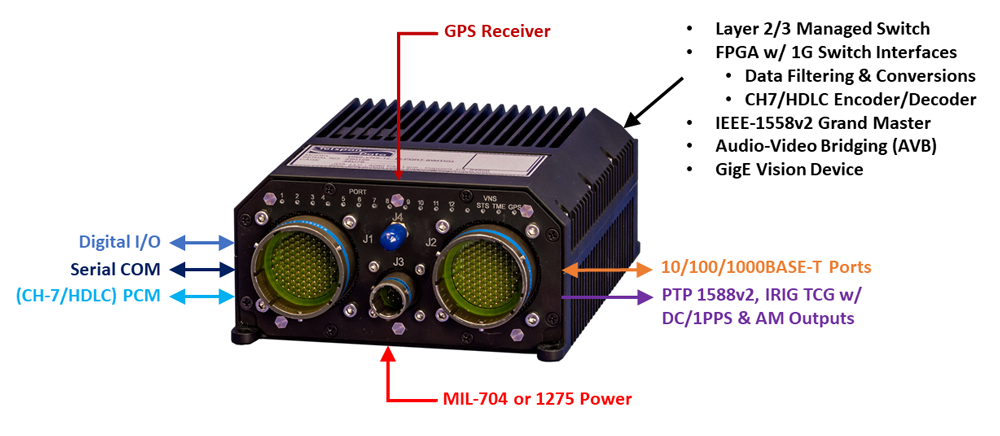

integrated Ethernet Switch

In network implementations, switches were typically single-purpose units for switching and routing Ethernet traffic. In the case of managed switches, the user could implement traffic-policing policies, setup Virtual Local Area Networks (VLAN’s) and assign traffic priorities among other management functions.

The integrated Ethernet Switch (iES) not only provides layer 2/3 switch management but also adds a Global Positioning System (GPS) receiver, independent hardware-based IEEE-1588 time engines with Grand Master capability and IRIG Time Code Generation (TCG). Data driven & user commanded discrete outputs, Pulse Code Modulation (PCM) and serial inputs/outputs extend the capability of the switch. The iES-12 includes an FPGA interface, tied directly to the switch fabric, providing content level data filtering & processing across the switch ports. The result of this content filtering and processing is sending end-results to network destinations and/or telemetering a merged data sub-set via PCM (Chapter 4 or 7) or ISO/IEC 13239 High-Level Data Link Control (HDLC). Learn More

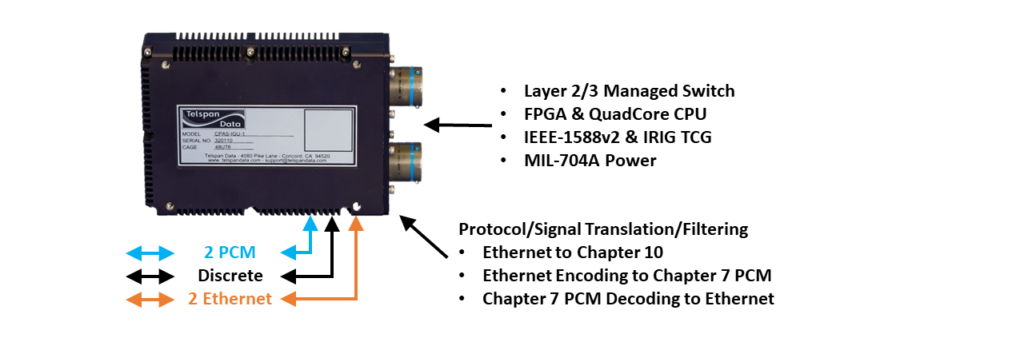

instrumentation Gateway

“Gateway” type applications typically perform protocol or signal translations. The instrumentation Gateway Unit (iGU) provides Ethernet interfaces w/ network timing, PCM input/output and a layer 2/3 managed switch. These interfaces are tied together in the Switched Data Fabric (SDF) to the integrated FPGA and CPU providing a wide array of capability in a single unit.

The FPGA and CPU provide real-time data processing or translation tasks including; IRIG 106 Chapter 10 publishing, Ethernet (including Chapter 10, DARv3, TmNS) to IRIG 106 Chapter 7 PCM Encoding/Decoding. This allows a user to combine sources of ethernet data, like video or other proprietary data formats, and convert it to Chapter 10 while sending to a recorder over Ethernet and outputting PCM to a transmitter for telemetering of that data. Additionally, data filtering and merging of network based DAU data into a sub-set IRIG 106 Chapter 4 PCM frame and any number of other user driven processes are possible with an iGU. Learn More

Modular Instrumentation TAP & Recorder

Traditionally, recorders were single purpose boxes that stored data in proprietary formats. The Modular Instrumentation TAP Recorder, aka MITR, is another example of a modern Multi-Disciplined Product Architecture. The MITR is a high-speed/high-capacity IRIG 106 Chapter 10 compliant recorder/publisher with Removeable Memory Module, TAP & Interface Module and Management Bay.

Much like the iES, MITRs Management Bay includes a managed integrated layer 2/3 managed Ethernet switch, GPS receiver, independent hardware-based IEEE-1588 time engines w/ Grand Master capability, IRIG TCG, multiple Ethernet interfaces, MIL-STD-1553 remote terminal or bus monitor operations and bi-directional PCM serial encoding/decoding of published IRIG 106 Chapter 10 or Ethernet traffic using or IRIG 106 Chapter 4/7 formats.

The optical TAP & Interface Module (TIM) provides up to 12 channels of DC-10G protocol independent transceivers as an in-line TAP or up to 24 channels of receive end-points. The signaling protocols reside within the logic fabric for Ethernet, Fibre-Channel, Firewire, Serial Front Panel Data Port (sFPDP) and others. Other TIM’s, with 8 channels of 1G copper Fibre- Channel, 12 channels of 10/100/1000BASE-T and a mix of optical/copper are available. Since the transceivers are protocol independent, the TIM channels can be configured for all of one protocol or mixed/matched and changed with a firmware load (via the RMM), easily allowing the MITR to adapt to many different test requirements.

The RMM, with a current total capacity up to 48TB and recording bandwidths from 1.5GBps (SATA) to 9GBps (NVMe), consists of 1 to 3 drives in a single carrier. Each carrier includes a built-in 10GE download port eliminating the need for expensive, standalone debrief stations. Data channels can be written to individual drives sustaining the very high aggregate rate recording. MITR’s RMM’s can also be configured as a Network Attached Storage (NAS).

MITR contains a unique, logic based Switched Data Fabric (SDF) between the TIM, Management Bay and Removable Memory Module (RMM). The high-speed SDF currently provides 230 Gbps of bandwidth across its data lanes which allows line speed filtering, processing, recording and publishing of incoming high-speed signal data. Inclusive/exclusive filtering setup consists of conditional frame level, Upper Protocol Level (UPL), and data content level from all physical channels as well as multiple virtual channels.

User programmed channel groups can consist of physical channels from the TIM and or Ethernet switch interfaces along with virtual channels derived from the physical inputs. The channel groups are then linked to destinations across the fabric to include individual or all RMM drives, IRIG 106 Chapter 10 data streaming publish ports in the Ethernet switch and encoded serial outputs. This allows both truth data to be recorded and filtered “quick-look” data to be recorder and/or simultaneously published/telemetered. Learn More

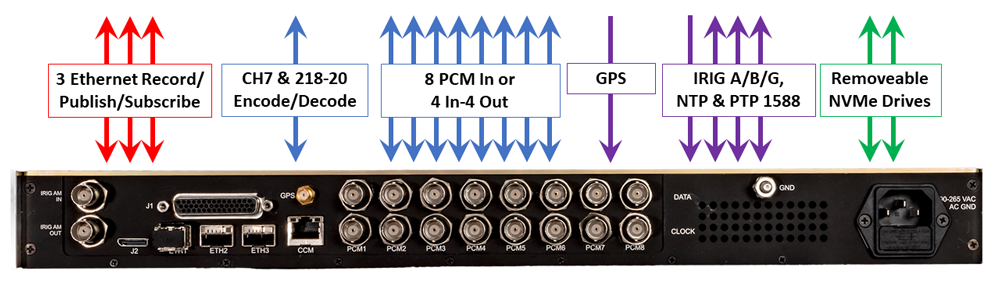

Telemetry Ground Systems

The multi-disciplined architecture is not limited to rugged airborne and ground vehicle products. Range and laboratory products can also benefit from this approach to reduce the number of individual single purpose systems. The 3rd Generation DataHUB is an open standards-based telemetry ground system with IRIG 106 Chapter 10 recorder/reproducer capabilities.

In addition to this, the DataHUB provides IRIG Chapter 10 publish/subscribe, data filtering/processing, IRIG 106 Chapter 7 encoding/decoding, GPS, IEEE-1588 PTP, NTP and IRIG time generation. Being multi-disciplined, the DataHUB adds THoIP Gateway functionality supporting both IRIG 106 CH7 and 218-20 encoding/decoding – all in a single unit. The 1U DataHUB provides up to 8 bi-directional PCM channels, 2 analog channels and 3 Ethernet channels. A portable version of DataHUB provides all the same features but in a small form factor. A 2U version of DataHUB adds a signal expansion card capability which increases the PCM channel counts to 32 and a best Source Selection (BSS) capability in accordance with IRIG 106 Chapter 2 Data Quality Metrics/Data Quality Encapsulation (DQM/DQE).

The DataHUB core system is driven by an SoC and Linux, not a Windows based host computing system. Command, control and status are via external discrete’s, Command Line Interface (RS-232 or TELNET) or a browser based Graphical User Interface (GUI). The DataHUB is a single system that provides all the capabilities needed in a modern telemetry ground recording, reproducing and distribution station. Learn More

Data Fusion & Display

A modern instrumentation system contains many potential sources of data – recorders, real-time streams and other network-based instrumentation devices which generate tons of data. Managing all that data is easy with NetView Data Fusion & Display.

NetView provides real-time decoding, processing, display & distribution from multiple IRIG 106 Chapter 10 data sources & network-based instrumentation systems. NetView decodes, time aligns, processes & displays multiple independent data source types & formats in a single processing & display environment.

NetView is a turnkey software application with real-time data displays capability including; video, 2D/3D map, HUD, XY plot, line graph, etc. Raw data displays provide the ability to drive down into the bit/word level of PCM, 429, 1553 and 1394 data streams. NetView capabilities are extended with a complete SDK allowing a user to develop their own custom GUI displays & access the data structure for end user defined decoders & special processing of measurements. Learn More

Summary

Instrumentation Engineers have always faced integration dilemmas associated with multi-unit architectures from data acquisition units, time generators, recorders, protocol convertors, GPS receivers, video compressors, data distribution units, etc. SWaP is becoming more of a concern due to smaller test articles and limited space for adding expanding instrumentation requirements. Single vendor integrated solutions are problematic due to proprietary methods, lack of open standards, and preventing the system designer from the selecting the “best in breed technologies”. Telspan Data’s Multi-Disciplined Products leverage open standards and the latest SoC, data transmission and processing technologies. These products give Instrumentation engineers unparalleled flexibility and capability with a means to field upgrade/modify the behavior of hardware as the testing requirements change and grow.